The dawn of Japanese porcelain began in Arita.

Soon, we’ll mark the 400th anniversary of the creation of Arita ware. The story of Arita ware is also the history of Japanese porcelain.

At the beginning of the 17th century, porcelain stone, the raw material from which porcelain is made, was discovered by the Korean potter Kanagae Sanbei (known as Yi Sam-pyeong in Korean) and his associates, revolutionizing the production of ceramics in Japan, where stoneware had been the principal ceramic ware until that time.

Kanagae, who was brought back to Japan by the Nabeshima clan during Toyotomi Hideyoshi’s attempted conquest of the Korean peninsula, initially set about making ceramics in Taku, which is located 30 kilometres from Arita. However, he settled down on the west side of Arita in 1616, and a strong desire to create white porcelain drove him to set out on a search for the raw material from which porcelain is made. This quest is said to have eventually led to the discovery of the Izumiyama quarry in the town of Arita.

High-quality Izumiyama porcelain stone became an enormously profitable product overnight, and production structures focusing on porcelain were established under the strict management of the Saga domain and its Sarayama magistrates. Products changed significantly as they evolved from the simple porcelains known as Shoki Imari (Early Imari) to elaborate designs in the Chinese style, eventually earning high praise from Europe’s royal family and the nobility.

Of the Izumiyama quarry, it is said that a mountain was transformed into ceramics over the course of 400 years. If the Korean Kanagae Sanbei, who combined shrewdness as a potter with the charisma necessary to lead his associates, had not set foot in Arita, the flowering of Japanese porcelain culture would presumably have been delayed. His approach and technical skill have been inherited over time by his descendants, including the 14th-generation Kanagae Sanbei and numerous other potters, who continue to keep them alive in Arita, a community that is defined by its ceramic industry.

有田から日本磁器の夜明け

『有田焼』はまもなく創業400年を迎える。これは、いわゆる日本磁器の歴史でもある。

17世紀初頭、朝鮮人陶工・李参平こと金ヶ江三兵衛らによって磁器の原料となる陶石が発見され、土ものの陶器が主流だった日本の陶磁器生産に大変革をもたらした。

豊臣秀吉の朝鮮出兵の際、鍋島勢によって連れて来られた李参平らは、当初は多久で製陶に従事。しかし、白磁を作りたいという強い思いから、磁器の原料を求めて探索の旅に出る。そうして1616年、ついにここ有田町で 『泉山磁石場』を発見したと言われている。

良質の泉山陶石は瞬く間に大金を生むドル箱商品となり、佐賀藩・皿山代官所の厳しい管理下で磁器中心の生産体制が確立された。製品は〈初期伊万里〉と呼ばれる素朴なものから、中国風の華やかなデザインへと大きく変化していき、ヨーロッパの王侯貴族たちの間で大いにもてはやされた。

〈400年かけて、ひとつの山をやきものに変えた〉といわれる『泉山磁石場』。陶工としての凄腕と、仲間を統率するカリスマ性を併せ持った李参平という朝鮮人が、この地を踏むことがなければ、日本の磁器文化の開花はもっと遅れていたことだろう。彼の想いと技術は、時を経た今も子孫の十四代・金ヶ江三兵衛さんや、多くの陶工たちによって受け継がれ、窯業のまち・有田にしっかりと息づいている。

-

Izumiyama porcelain stone

泉山陶石 -

Statue of Kanagae Sanbei, the creator of Arita ware (at Ishiba Shrine)

陶祖李参平象(石場神社内)

The appeal of Izumiyama as a power spot

I visited Izumiyama for the first time in early spring, which is to say, while it was still being swept by cold winds. These days the place has become one of the town’s sightseeing destinations, complete with a promenade, but it’s likely that it was just a rugged, densely forested mountain when Kanagae Sanbei arrived.

But when you stand here, somehow the air seems cleaner. The place exudes a mysterious ambiance that makes it feel as though the wind blowing through purifies you from your feet up.

These days the word “spiritual” has become popular, and Izumiyama has a hidden power that's no less real for not being visible. Perhaps it’s the life force of those predecessors of ours who worked so diligently under these same blue skies that fuels this power.

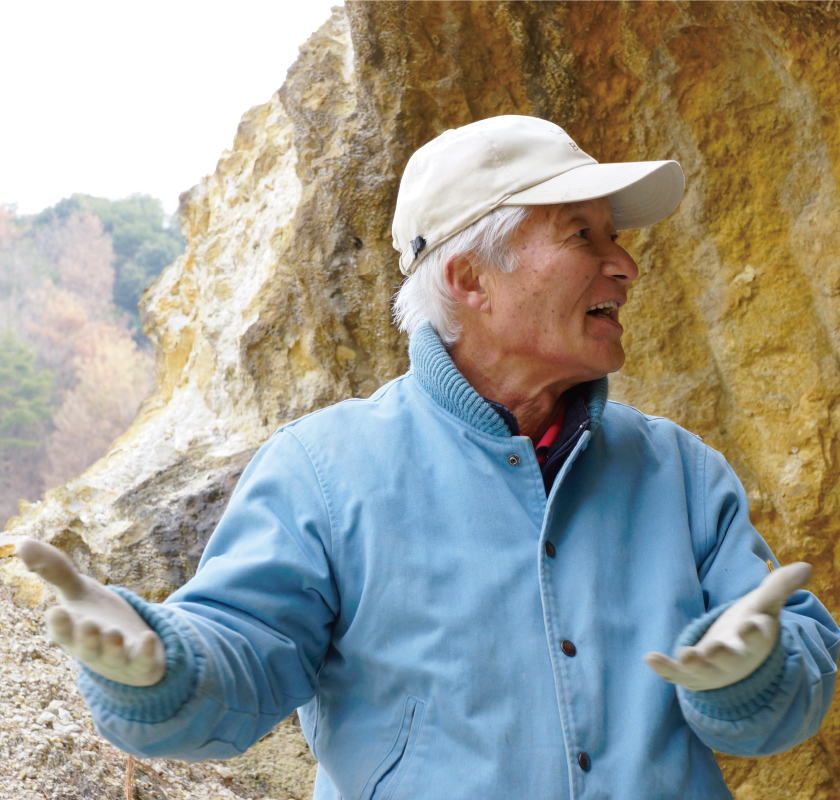

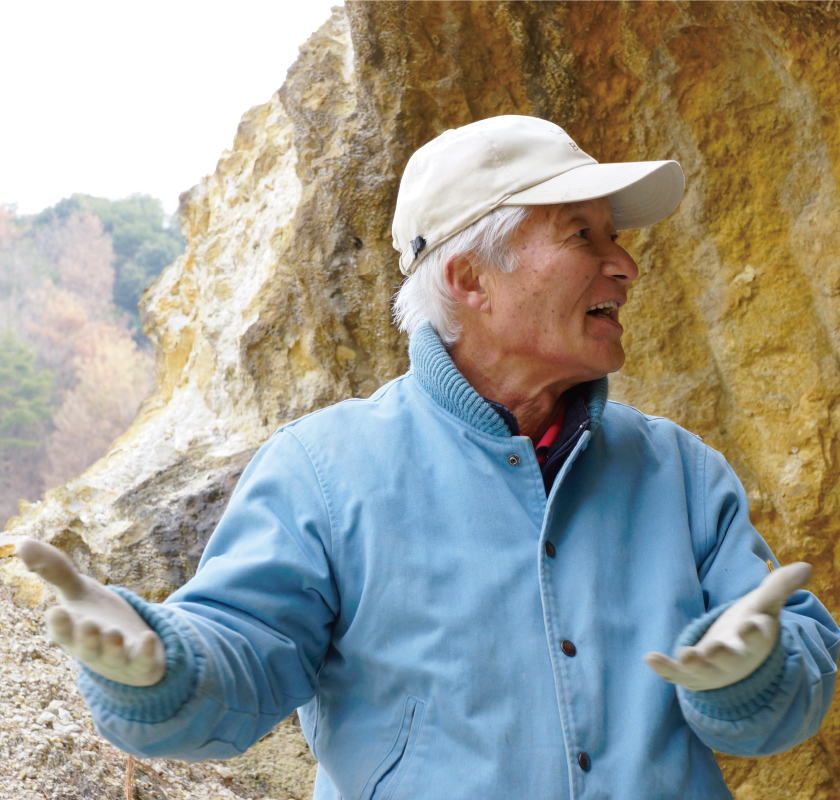

Describing his special feelings for Izumiyama, Fujimoto Kakushi (67), 9th-generation Fujimaki Seito and chairman of the Arita Porcelain Quarry Association, said, “When I come here, I sense the passionate energy of all those forebears who were involved with Arita ware. I'm proud that of all the stone mines in Japan, only Arita managed to transform mere rock into treasure.

They were still excavating stone by hand at the time. It was truly hard work, transporting the stone after quarrying it and then crushing it to turn it into clay. Porcelain stone is a natural resource, so it doesn’t exhibit uniform quality. How they classified it according to grade in an era when test data didn't exist is an intriguing question. So when I look at the signs of past excavations at the quarry, I find myself imagining what they made with those raw materials.”

If we trace the history of Izumiyama porcelain stone, we find that millions of pieces of Arita ware were exported to Europe, where they became extremely popular, starting during the mid 17th century. At about the same time, the Saga domain opened an official kiln at Okawachiyama and began producing gifts for powerful lords using the highest-grade Izumiyama porcelain stone and technically skilled official craftsmen.

A mass production system developed over time as Arita porcelain became popular among ordinary people, and most products were being made from Amakusa porcelain stone from Kumamoto, which has lower iron content, by the second half of the Meiji period (1868-1912). Reflecting the difficulty of forming and firing Izumiyama porcelain stone due to its lack of stickiness, the percentage of products made from the material had fallen below 30% by the beginning of the Showa period (1926-1989).

Nonetheless, the surface of white porcelain made with raw material from Izumiyama has a distinctive blue tint, thus earning praise for a level of elegance and refinement that differs from works made from Amakusa porcelain stone. Recognising that today, Izumiyama porcelain stone is only used as a raw material for certain products, including tiles and acid-resistant porcelain, Fujimoto is calling on kiln owners to get back to the origins of Arita ware and rebuild the potential of Izumiyama porcelain stone.

“I believe that Izumiyama is the site of a struggle by the spirit of today’s ceramic artists and those of generations past,” says Fujimoto. “No matter the era, there have been times when it was difficult to make a living by means of ceramics alone. Nonetheless, our predecessors refined their knowledge and came together to pass down Izumiyama to later generations. I believe our mission is to search for a path with the potential to transform this mountain into a source of treasures again in the future and to pass that on to young artists.”

As we approach the 400th anniversary of the creation of Arita ware, some ceramic artists are already starting to search for a new way forward. These efforts are gradually giving rise to ceramics that will blow a new wind into an industry that has been stagnating.

パワースポット『泉山』の魅力を語る

早春とはいえまだ寒風の吹く中、初めて『泉山』を訪ねた。今でこそ歩道も整備され、まちの観光スポットになっているが、李参平が訪れた当時は、おそらくあたりは鬱蒼としたただの岩山だったと思われる。

しかし、ここに立つと心なしか空気の澄み方が違う。通り抜ける風は足もとから浄化されていくような神秘さを感じさせてくれる。

近頃スピリチュアルという言葉が流行っているが、目には見えなくとも、その地に秘められたパワーは存在する。その力強さの由縁は、きっとこの大空の下で懸命に生きた先人たちの命火なのではないだろうか。

「ここに来ると、有田焼に携わった全先人たちの熱いエネルギーを感じるんです。日本中に採石場はあっても、ただの石を宝物に変えたのは有田だけだと自負しています」。

『藤巻製陶』9代目で、有田磁石場組合議会議長の藤本覚司さん(67)は、泉山への特別な思いを語ってくださった。

「当時は手掘りだったでしょうから、採石後に石を運び出し、砕石して土にするという、実に手間のかかる作業をやっていたわけですよね。それに陶石は天然資源なので質も均一ではないですし、試験データもない時代に等級の区別はどのようにしていたのかと感心します。ですから、こうして石場の中に入って掘削の跡を見ると、ここの原料でどんなものを作ったんだろうかとつい想像してしまうんです」。

泉山陶石の変遷をたどると、17世紀の半ばから、数百万個の有田焼がヨーロッパに輸出されて大ブレイク。同じ頃、佐賀藩は大川内山に御用窯を開き、最上級の泉山陶石と技術の優れた御用職人を使って、有力大名への献上品の製造を行なっていた。

しだいに有田の磁器が庶民階級まで普及するにつれて量産体制に入り、明治後期には鉄分の少ない熊本・天草陶石を原料とした製品が主流に。泉山陶石は粘り気がなく、成形や焼成に難点があるため、昭和初期には泉山陶石の使用比率は30%を割り込むまでになってしまった。

しかし、泉山の原料で作られた白磁面には独特の青みがあり、天草のそれとはひと味違った気品と格調の高さが高く評価されている。現在ではタイルや耐酸磁器などの一部の原料として使われているのみで、それだけにもう一度『有田焼』の原点に戻って、泉山陶石の可能性を再構築したいと、藤本さんらは窯主たちに呼びかけている。

「泉山は、今と昔の陶工者たちとの魂の格闘の場だと思っています。いつの時代もやきものだけで食べていくには困難な状況があり、でもそんな中でも先人たちは知恵を絞り、団結して、この泉山を後世に残してくれました。これからの未来、ここが再び宝の山となるよう可能性の道筋を探して、若手に引き継いでいくことが我々の使命だと思っています」

有田焼創業400年を前に、一部の窯主たちの間では早くも新たなる一歩が模索し始められている。低迷しているやきもの業界に新風を起こすやきものが、今ゆっくりとこのまちで生まれようとしている。

-

Fujimoto Kakushi, 9th-generation Fujimaki Seito and chairman of the Arita Porcelain Quarry Association

藤巻製陶9代目で、有田磁石場組合議会議長の藤本覚司さん -

Former excavation sites

採掘口跡 -

-

-

-

-

The appeal of Izumiyama as a power spot

I visited Izumiyama for the first time in early spring, which is to say, while it was still being swept by cold winds. These days the place has become one of the town’s sightseeing destinations, complete with a promenade, but it’s likely that it was just a rugged, densely forested mountain when Kanagae Sanbei arrived.

But when you stand here, somehow the air seems cleaner. The place exudes a mysterious ambiance that makes it feel as though the wind blowing through purifies you from your feet up.

These days the word “spiritual” has become popular, and Izumiyama has a hidden power that's no less real for not being visible. Perhaps it’s the life force of those predecessors of ours who worked so diligently under these same blue skies that fuels this power.

Describing his special feelings for Izumiyama, Fujimoto Kakushi (67), 9th-generation Fujimaki Seito and chairman of the Arita Porcelain Quarry Association, said, “When I come here, I sense the passionate energy of all those forebears who were involved with Arita ware. I'm proud that of all the stone mines in Japan, only Arita managed to transform mere rock into treasure.

They were still excavating stone by hand at the time. It was truly hard work, transporting the stone after quarrying it and then crushing it to turn it into clay. Porcelain stone is a natural resource, so it doesn’t exhibit uniform quality. How they classified it according to grade in an era when test data didn't exist is an intriguing question. So when I look at the signs of past excavations at the quarry, I find myself imagining what they made with those raw materials.”

パワースポット『泉山』の魅力を語る

早春とはいえまだ寒風の吹く中、初めて『泉山』を訪ねた。今でこそ歩道も整備され、まちの観光スポットになっているが、李参平が訪れた当時は、おそらくあたりは鬱蒼としたただの岩山だったと思われる。

しかし、ここに立つと心なしか空気の澄み方が違う。通り抜ける風は足もとから浄化されていくような神秘さを感じさせてくれる。

近頃スピリチュアルという言葉が流行っているが、目には見えなくとも、その地に秘められたパワーは存在する。その力強さの由縁は、きっとこの大空の下で懸命に生きた先人たちの命火なのではないだろうか。

「ここに来ると、有田焼に携わった全先人たちの熱いエネルギーを感じるんです。日本中に採石場はあっても、ただの石を宝物に変えたのは有田だけだと自負しています」。

『藤巻製陶』9代目で、有田磁石場組合議会議長の藤本覚司さん(67)は、泉山への特別な思いを語ってくださった。

「当時は手掘りだったでしょうから、採石後に石を運び出し、砕石して土にするという、実に手間のかかる作業をやっていたわけですよね。それに陶石は天然資源なので質も均一ではないですし、試験データもない時代に等級の区別はどのようにしていたのかと感心します。ですから、こうして石場の中に入って掘削の跡を見ると、ここの原料でどんなものを作ったんだろうかとつい想像してしまうんです」。

-

Fujimoto Kakushi, 9th-generation Fujimaki Seito and chairman of the Arita Porcelain Quarry Association

藤巻製陶9代目で、有田磁石場組合議会議長の藤本覚司さん -

Former excavation sites

採掘口跡

If we trace the history of Izumiyama porcelain stone, we find that millions of pieces of Arita ware were exported to Europe, where they became extremely popular, starting during the mid 17th century. At about the same time, the Saga domain opened an official kiln at Okawachiyama and began producing gifts for powerful lords using the highest-grade Izumiyama porcelain stone and technically skilled official craftsmen.

A mass production system developed over time as Arita porcelain became popular among ordinary people, and most products were being made from Amakusa porcelain stone from Kumamoto, which has lower iron content, by the second half of the Meiji period (1868-1912). Reflecting the difficulty of forming and firing Izumiyama porcelain stone due to its lack of stickiness, the percentage of products made from the material had fallen below 30% by the beginning of the Showa period (1926-1989).

Nonetheless, the surface of white porcelain made with raw material from Izumiyama has a distinctive blue tint, thus earning praise for a level of elegance and refinement that differs from works made from Amakusa porcelain stone. Recognising that today, Izumiyama porcelain stone is only used as a raw material for certain products, including tiles and acid-resistant porcelain, Fujimoto is calling on kiln owners to get back to the origins of Arita ware and rebuild the potential of Izumiyama porcelain stone.

“I believe that Izumiyama is the site of a struggle by the spirit of today’s ceramic artists and those of generations past,” says Fujimoto. “No matter the era, there have been times when it was difficult to make a living by means of ceramics alone. Nonetheless, our predecessors refined their knowledge and came together to pass down Izumiyama to later generations. I believe our mission is to search for a path with the potential to transform this mountain into a source of treasures again in the future and to pass that on to young artists.”

As we approach the 400th anniversary of the creation of Arita ware, some ceramic artists are already starting to search for a new way forward. These efforts are gradually giving rise to ceramics that will blow a new wind into an industry that has been stagnating.

泉山陶石の変遷をたどると、17世紀の半ばから、数百万個の有田焼がヨーロッパに輸出されて大ブレイク。同じ頃、佐賀藩は大川内山に御用窯を開き、最上級の泉山陶石と技術の優れた御用職人を使って、有力大名への献上品の製造を行なっていた。

しだいに有田の磁器が庶民階級まで普及するにつれて量産体制に入り、明治後期には鉄分の少ない熊本・天草陶石を原料とした製品が主流に。泉山陶石は粘り気がなく、成形や焼成に難点があるため、昭和初期には泉山陶石の使用比率は30%を割り込むまでになってしまった。

しかし、泉山の原料で作られた白磁面には独特の青みがあり、天草のそれとはひと味違った気品と格調の高さが高く評価されている。現在ではタイルや耐酸磁器などの一部の原料として使われているのみで、それだけにもう一度『有田焼』の原点に戻って、泉山陶石の可能性を再構築したいと、藤本さんらは窯主たちに呼びかけている。

「泉山は、今と昔の陶工者たちとの魂の格闘の場だと思っています。いつの時代もやきものだけで食べていくには困難な状況があり、でもそんな中でも先人たちは知恵を絞り、団結して、この泉山を後世に残してくれました。これからの未来、ここが再び宝の山となるよう可能性の道筋を探して、若手に引き継いでいくことが我々の使命だと思っています」

有田焼創業400年を前に、一部の窯主たちの間では早くも新たなる一歩が模索し始められている。低迷しているやきもの業界に新風を起こすやきものが、今ゆっくりとこのまちで生まれようとしている。

The radiance of Ko-Imari being reborn through the revitalisation of the Izumiyama quarry

“I guess it was around last June,” recollects Higuchi Norito (65), who’s working with Master Arita craftsman Okugawa Shun’emon (63) to reproduce Edo-period (1603-1868) Ko-Imari works in the Kakiemon style using Izumiyama porcelain stone. “The two of us were saying how we’d like to create Ko-Imari using stone from Izumiyama. It was a deeply meaningful project that anyone who creates ceramics in Arita would find truly rewarding.”

The two artists began by visiting quarries and gazing at the layers of rock until they found what they were looking for. Then they studied clay preparation techniques used at the time, drawing clues from old texts.

Clay preparation consists of dissolving pulverised stone in water, stirring the mixture, and then drawing off only the top layer of liquid, known as supernatant. Then the trick is to prepare the mixture by adding clay which is suitably coarse and as much white clay as possible to give it plasticity. It was their intuition as master craftsmen of wheel throwing, which is to say, their highly skilled fingers, that told them when the mixture was ready.

“Once the clay was complete, we visited The Kyushu Ceramic Museum and sought advice about what to make from the director. That process led us to decide to try making a decagonal Kakiemon-style Ko-Imari dish measuring about 24 centimetres across,” recounted Okugawa. “Examining the original dish, I saw that it was carefully crafted down to the finest level of detail, which gave me a new appreciation of how important wheel-throwing skill is. How was such an elaborately detailed porcelain made in an era that lacked tools? Ours was a process of trial and error as we imagined how our predecessors had crafted such works.”

When I’m shown the finished work, I find it has the ambiance of an antique and the air of the Edo period, and I feel that I’ve touched the origin of Arita ware.

“By using authentic materials, we were able to create an extremely nuanced work,” said Okugawa. “We hope to differentiate ourselves by using raw materials from Izumiyama in the future and to safeguard the fundamental nature of Arita ware. Now we just need to figure out how to mass-produce clay made from Izumiyama porcelain stone.”

A master craftsman’s challenges never end.

泉山復興で甦る古伊万里の輝き

「昨年の 6月頃からだったでしょうか。泉山の石を使って古伊万里をやりたいねって、ふたりで話したのは。有田でやきものを作る者としては、実に挑戦しがいのある奥深い取り組みでした」。

泉山陶石を使って、江戸時代の古伊万里・柿右衛門の復刻を行っているのは、有田の名工・奥川俊右衛門さん(63)と樋口憲人さん(65)。お二人はまず磁石場に足を運び、石の層をじっくりと眺めて、採掘場に狙いをつけた。そして、古い文献を手がかりにして、当時の土作りを学ばれたようだ。

土作りはまず砕いた石を水に溶かし、かくはん後にその上澄みだけを掬い取る。次に適度に粗くて、できるだけ白い土を加え、土に可塑性(粘り気)を出すのがポイント。そのよしあしを知るのは、土をいじるろくろ師の勘、つまり熟練の手指が教えてくれた。

「土が完成したのを機に九州陶磁文化館に出向き、何を作るかを館長とも相談しながら、古伊万里・柿右衛門の八寸の十角皿にチャレンジしてみようということになりました。当時の作品を観察すると、細部に至るまでものすごく丁寧な作りで、ろくろの技術がいかに重要だったかを再認識しました。道具のない時代にどうやってここまで繊細巧妙な作品が作れたのか、すべてが先人のやり方を想像しながらの試行錯誤でした」。

完成品を見せていただくと、それは江戸時代の空気をはらんだ骨董の雰囲気漂う器で、これこそ有田焼の原点に触れた思いがした。

「本物の材料を使うことで、非常に味のある作品が生まれました。今後は泉山の原料を使うことで差別化を図り、元来の有田焼を守っていけたらと思います。あとは泉山陶石を原料にした土をどうやって量産していくかが課題です」。

名工の挑戦に終わりはない。

-

Left side / Higuchi Norito of Norito Kiln

Right side / Okugawa Shun’emon of Shun’emon Kiln

On the table / Prototypes made using Izumiyama porcelain stone

左/乃利陶窯の樋口憲人さん

右/俊右衛門窯の奥川俊右衛門さん

テーブルの上/泉山陶石を使った試作品

-

Higuchi Norito of Norito Kiln

乃利陶窯の樋口憲人さん -

Okugawa Shun’emon of Shun’emon Kiln

俊右衛門窯の奥川俊右衛門さん -

Prototypes made using Izumiyama porcelain stone

泉山陶石を使った試作品